Design and Development

Blue Ridge Thermoforming has over 30 years of experience in designing and developing vacuum formed trays, packaging, and equipment covers. We specialize in providing innovative answers to challenges of pack density, product protection, and user functionality. We work with some of the most talented and experienced designers in this industry. All of our design work is done in SolidWorks. SolidWorks gives us the ability to review projects with customers before moving forward with prototypes and tools.

Design and Development

Blue Ridge Thermoforming has over 30 years of experience in designing and developing vacuum formed trays, packaging, and equipment covers. We specialize in providing innovative answers to challenges of pack density, product protection, and user functionality. We work with some of the most talented and experienced designers in this industry. All of our design work is done in SolidWorks. SolidWorks gives us the ability to review projects with customers before moving forward with prototypes and tools.

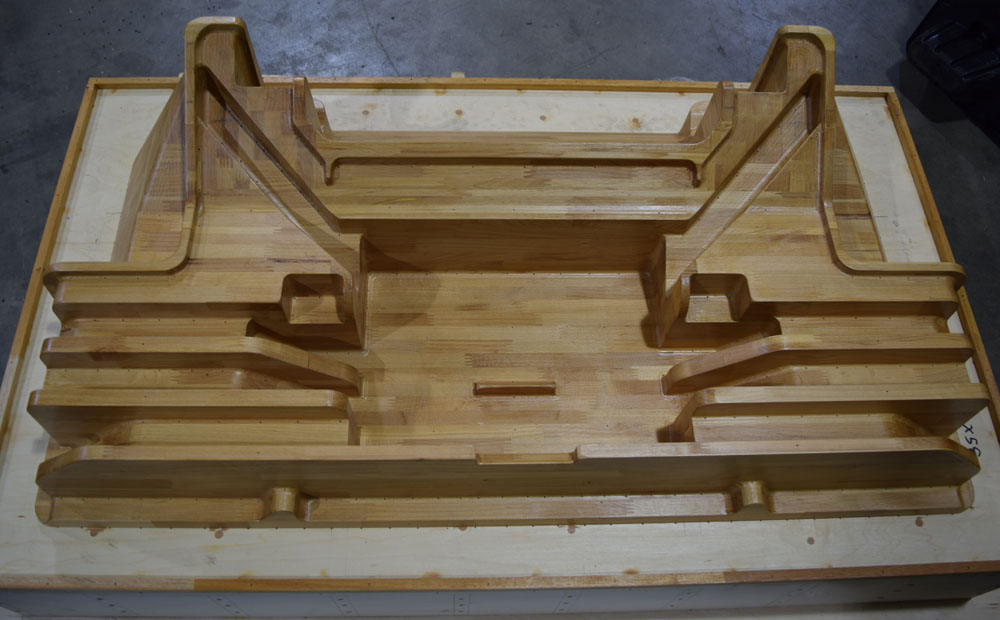

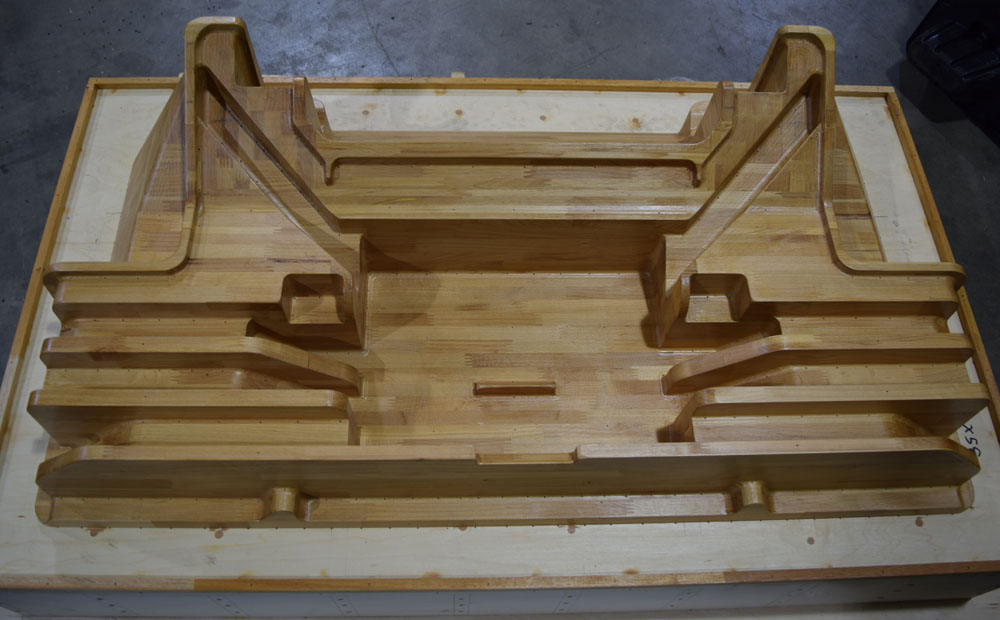

Prototyping

Need or want a prototype before purchasing production tooling? Not a problem, we have the ability to run wood or composite tools that can create up to 50 prototypes. Although it is possible to make modifications to aluminum production tools it is often costly and time consuming. Prototypes give our customers the ability to try the design and make changes before purchasing the aluminum production tools.

Prototyping

Need or want a prototype before purchasing production tooling? Not a problem, we have the ability to run wood or composite tools that can create up to 50 prototypes. Although it is possible to make modifications to aluminum production tools it is often costly and time consuming. Prototypes give our customers the ability to try the design and make changes before purchasing the aluminum production tools.

3D Printing

3D printing is another option when a prototype is needed. Sometimes it is cheaper and faster to print an image rather than building prototype tooling. Blue Ridge has several outsourced options for 3D printing. We commonly use a few local sources that offer fast turn around and high quality parts but also have used larger corporations that offer some of the largest printing capabilities that are available.

3D Printing

3D printing is another option when a prototype is needed. Sometimes it is cheaper and faster to print an image rather than building prototype tooling. Blue Ridge has several outsourced options for 3D printing. We commonly use a few local sources that offer fast turn around and high quality parts but also have used larger corporations that offer some of the largest printing capabilities that are available.

Tooling

Blue Ridge has partnerships with several great tooling companies. Whether it’s a machined thin gauge tool or a cast aluminum heavy gauge tool our customers are provided with high quality tools that can last through millions of cycles. We also have the ability to have 5-axis router fixtures, check fixtures, and assembly jigs built through our network of tooling companies that we work with.

Tooling

Blue Ridge has partnerships with several great tooling companies. Whether it’s a machined thin gauge tool or a cast aluminum heavy gauge tool our customers are provided with high quality tools that can last through millions of cycles. We also have the ability to have 5-axis router fixtures, check fixtures, and assembly jigs built through our network of tooling companies that we work with.