Thin Gauge Thermoforming

Blue Ridge Thermoforming has three thin gauge forming lines with inline cutting capability on all of the machines. The maximum size part that the equipment can run is a 30”x36” tray. Material thickness can range from .015” to .06”. Materials commonly run on our thin gauge lines are HIPS, PET/PETG, PVC, HDPE, HMWPE, LDPE, Poly Carbonate, and ABS. Blue Ridge has an environment controlled room that the thin gauge inline cutters feed directly into. This room acts as a clean room for inspecting and packaging sensitive trays.

Thing Gauge Thermoforming

Blue Ridge Thermoforming has three thin gauge forming lines with inline cutting capability on all of the machines. The maximum size part that the equipment can run is a 30”x36” tray. Material thickness can range from .015” to .06”. Materials commonly run on our thin gauge lines are HIPS, PET/PETG, PVC, HDPE, HMWPE, LDPE, Poly Carbonate, and ABS. Blue Ridge has an environment controlled room that the thin gauge inline cutters feed directly into. This room acts as a clean room for inspecting and packaging sensitive trays.

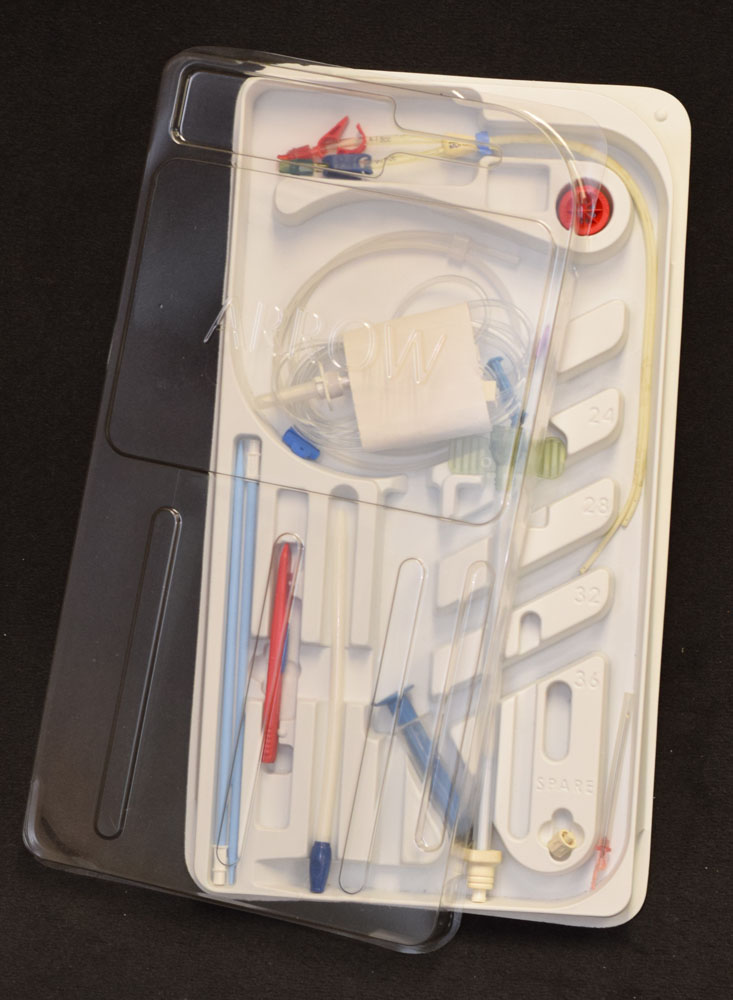

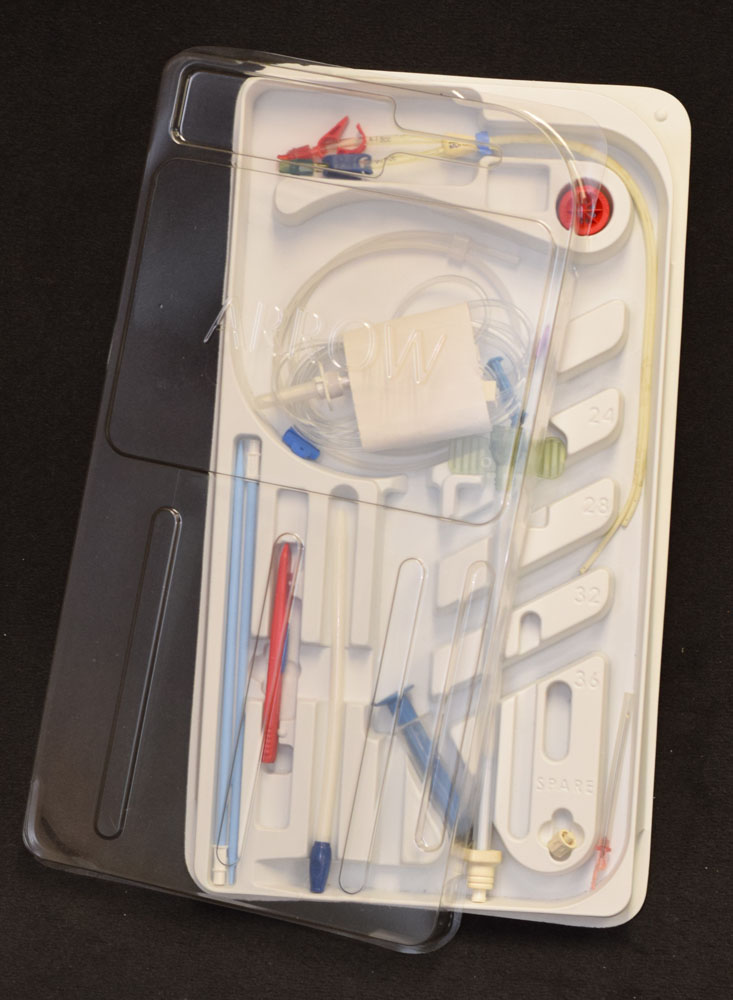

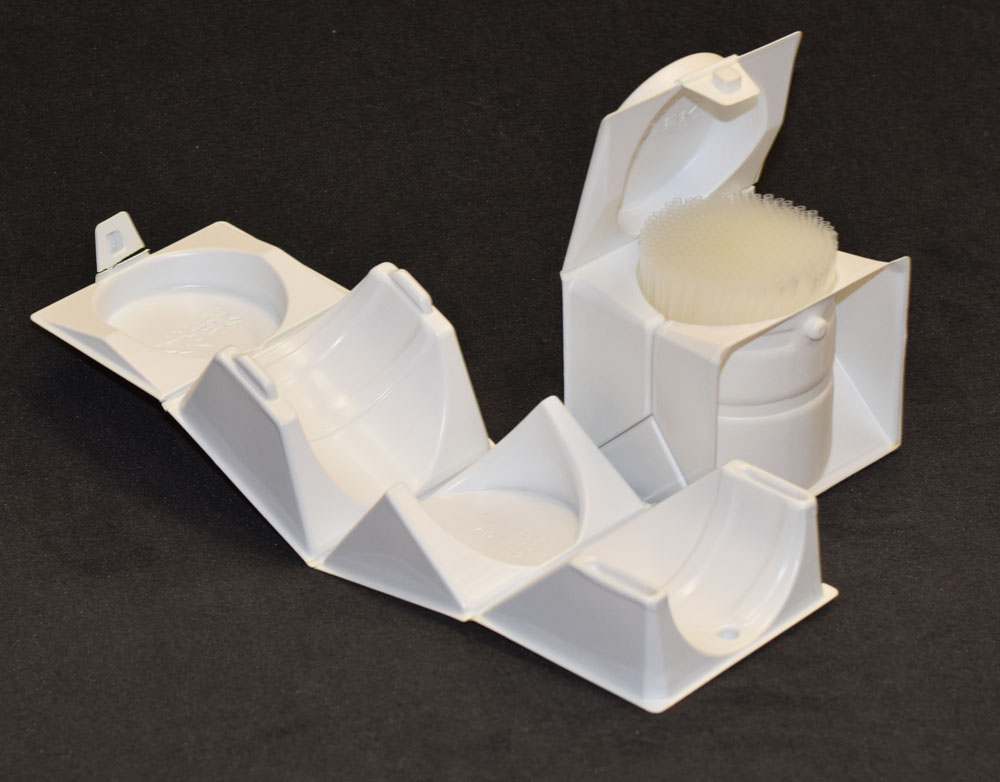

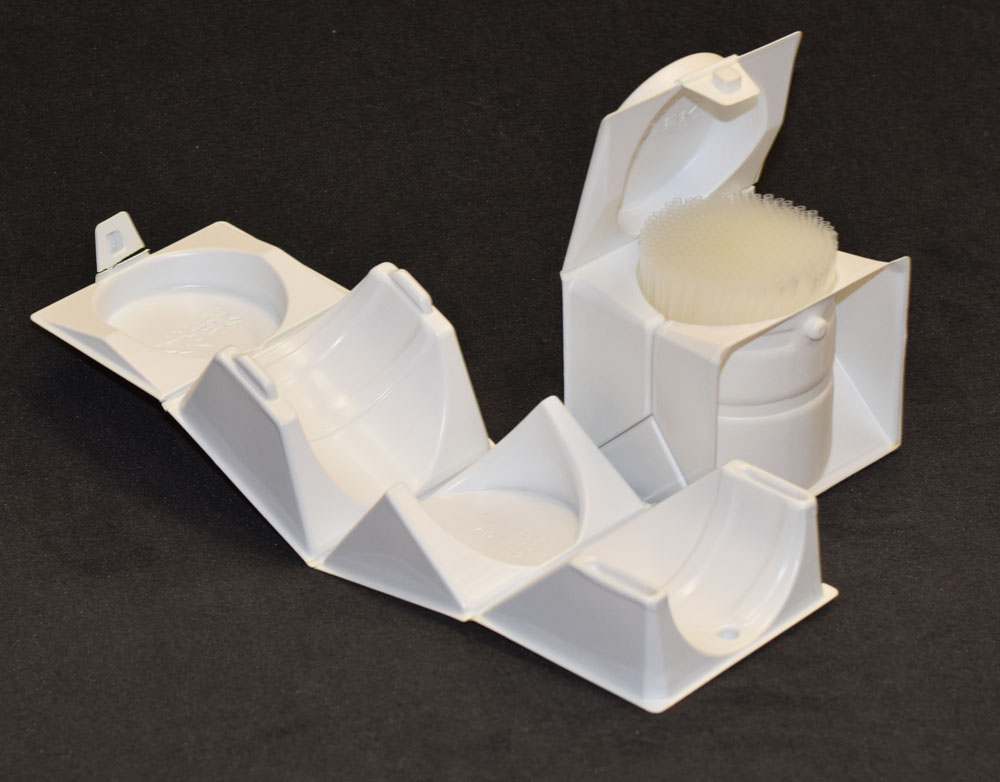

Medical Device Packaging

Blue Ridge Thermoforming is a FDA registered medical device packaging manufacturer with 20+ years of history designing and manufacturing medical device packaging. Trays and packaging can be designed for single device packaging, multiple device packaging, and full medical kit packaging. We feed our production lines into a controlled environment clean room to ensure that we are able to provide clean packaging to our medical device customers. Whether your tray is already designed, or if you just have a product that needs packaging, contact us for competitive pricing and excellent service.

Medical Device Packaging

Blue Ridge Thermoforming is a FDA registered medical device packaging manufacturer with 20+ years of history designing and manufacturing medical device packaging. Trays and packaging can be designed for single device packaging, multiple device packaging, and full medical kit packaging. We feed our production lines into a controlled environment clean room to ensure that we are able to provide clean packaging to our medical device customers. Whether your tray is already designed, or if you just have a product that needs packaging, contact us for competitive pricing and excellent service.

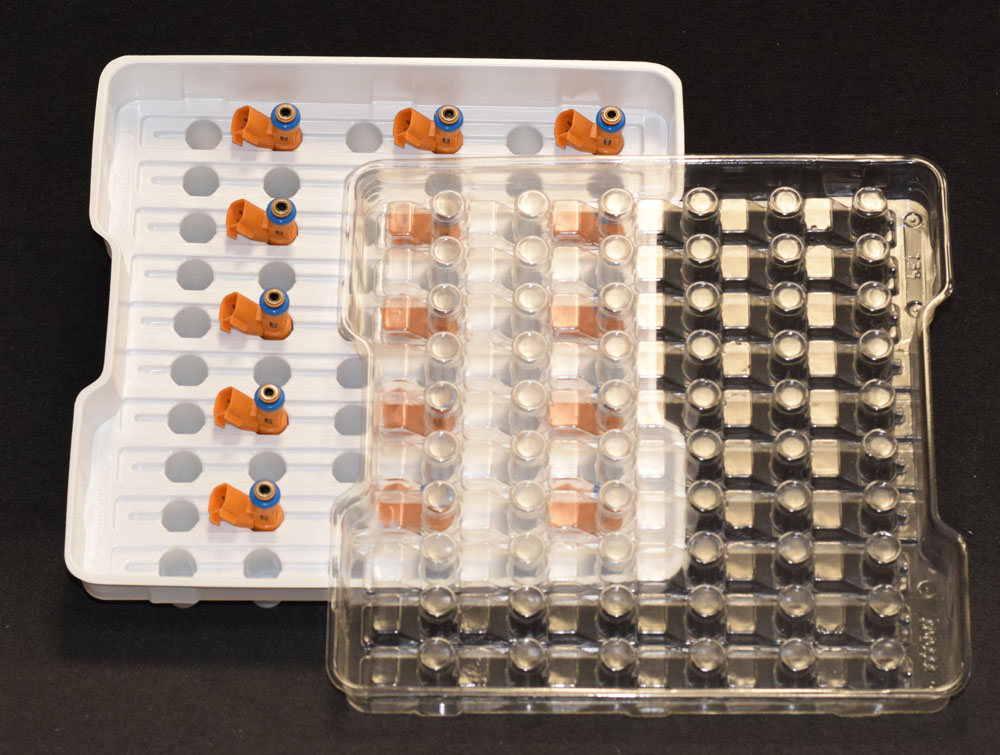

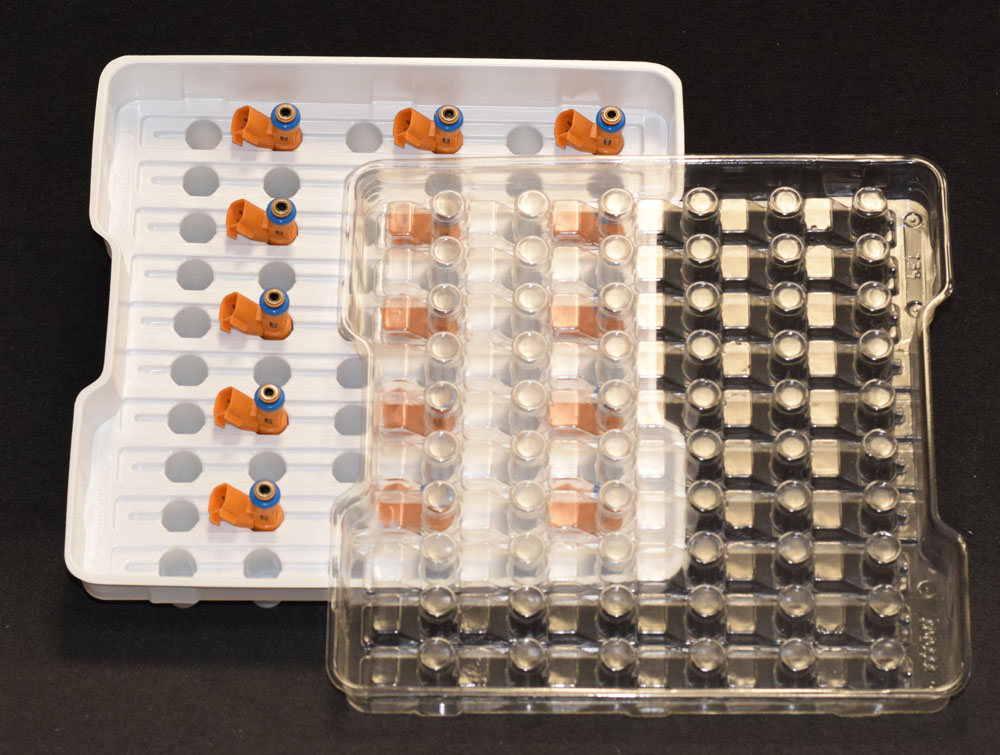

Industrial Packaging

Whether its capacitors, wire harness, bearings, or any other part that is challenging to package Blue Ridge can design a tray that will safely hold your parts. Our experience and design capabilities allow us to design packaging that not only protects the parts but also considers product presentation, ergonomics of loading and unloading the trays, and pack density.Whether your tray is already designed, or if you just have a product that needs packaging, contact us for competitive pricing and excellent service.

Industrial Packaging

Whether its capacitors, wire harness, bearings, or any other part that is challenging to package Blue Ridge can design a tray that will safely hold your parts. Our experience and design capabilities allow us to design packaging that not only protects the parts but also considers product presentation, ergonomics of loading and unloading the trays, and pack density.Whether your tray is already designed, or if you just have a product that needs packaging, contact us for competitive pricing and excellent service.

Clamshell

A clamshell is a one-piece container consisting of two halves joined by a living hinge which allows the packaging to come together and close. This type of packaging is commonly found in carry out food containers and consumer product packaging. Blue Ridge can design clamshells to be closed through snap fit or friction or we can design clamshells that will be sealed using sonic welding, adhesives, or staples. Contact us to discuss your packaging requirements and we can work on designing packaging to meet those needs.

Clamshell

A clamshell is a one-piece container consisting of two halves joined by a living hinge which allows the packaging to come together and close. This type of packaging is commonly found in carry out food containers and consumer product packaging. Blue Ridge can design clamshells to be closed through snap fit or friction or we can design clamshells that will be sealed using sonic welding, adhesives, or staples. Contact us to discuss your packaging requirements and we can work on designing packaging to meet those needs.

ESD and Anti-Static Packaging

Some electronic parts require anti-static or ESD (Electro Static Dissipative) packaging to ensure they are not damaged by the buildup of static electricity found in packaging. Blue Ridge is able to offer packaging trays and clamshells in anti-stat or ESD grade plastics. Anti-Static packaging trays will prevent the buildup of static while an ESD packaging tray will actually dissipate an electrical charge that is in the parts that are packaged.

ESD and Anti-Static Packaging

Some electronic parts require anti-static or ESD (Electro Static Dissipative) packaging to ensure they are not damaged by the buildup of static electricity found in packaging. Blue Ridge is able to offer packaging trays and clamshells in anti-stat or ESD grade plastics. Anti-Static packaging trays will prevent the buildup of static while an ESD packaging tray will actually dissipate an electrical charge that is in the parts that are packaged.

Blister Packaging

Blister pack is a term for several types of pre-formed plastic packaging used for small consumer goods, foods, and for pharmaceuticals. Blister packs consist of carded packaging where goods such as toys, hardware, and electrical items are contained between a specially made paperboard card and clear pre-formed plastic such as PVC or PETG. Contact Blue Ridge to discuss your blister packaging needs!

Blister Packaging

Blister pack is a term for several types of pre-formed plastic packaging used for small consumer goods, foods, and for pharmaceuticals. Blister packs consist of carded packaging where goods such as toys, hardware, and electrical items are contained between a specially made paperboard card and clear pre-formed plastic such as PVC or PETG. Contact Blue Ridge to discuss your blister packaging needs!