Capabilities

Blue Ridge Thermoforming has thin gauge and heavy gauge vacuum forming capabilities. We are a manufacturer of custom designed vacuum formed packaging and equipment covers. Because we are a custom manufacturer, we focus on meeting or exceeding customer expectations through high quality products, on time deliveries, excellent customer service and continuous improvement.

Capabilities

Blue Ridge Thermoforming has thin gauge and heavy gauge vacuum forming capabilities. We are a manufacturer of custom designed vacuum formed packaging and equipment covers. Because we are a custom manufacturer, we focus on meeting or exceeding customer expectations through high quality products, on time deliveries, excellent customer service and continuous improvement.

Thin Gauge Vacuum Forming

Blue Ridge has three thin gauge forming lines with inline cutting capability on all of the machines. The maximum size part that the equipment can run is a 30”x36” tray. Material thickness can range from .015” to .06”. Materials commonly run on our thin gauge lines are HIPS, PET/PETG, PVC, HDPE, HMWPE, LDPE, Poly Carbonate, and ABS. Blue Ridge has an environment controlled room that the thin gauge inline cutters feed directly into. This room acts as a clean room for inspecting and packaging sensitive trays.

Thin Gauge Vacuum Forming

Blue Ridge has three thin gauge forming lines with inline cutting capability on all of the machines. The maximum size part that the equipment can run is a 30”x36” tray. Material thickness can range from .015” to .06”. Materials commonly run on our thin gauge lines are HIPS, PET/PETG, PVC, HDPE, HMWPE, LDPE, Poly Carbonate, and ABS. Blue Ridge has an environment controlled room that the thin gauge inline cutters feed directly into. This room acts as a clean room for inspecting and packaging sensitive trays.

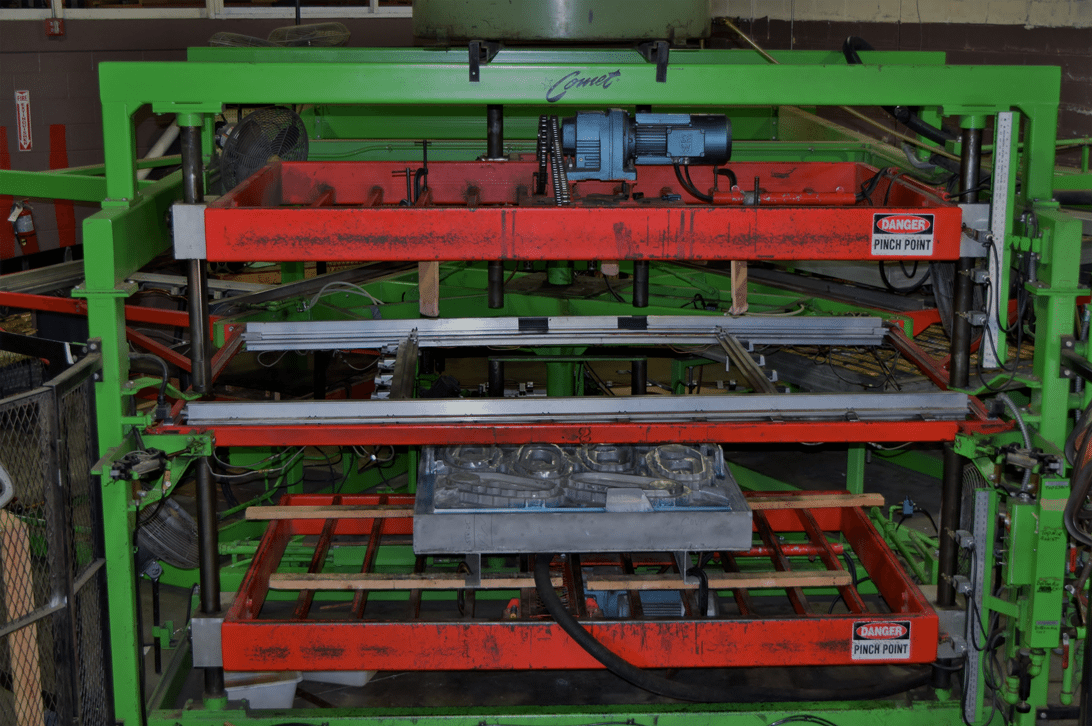

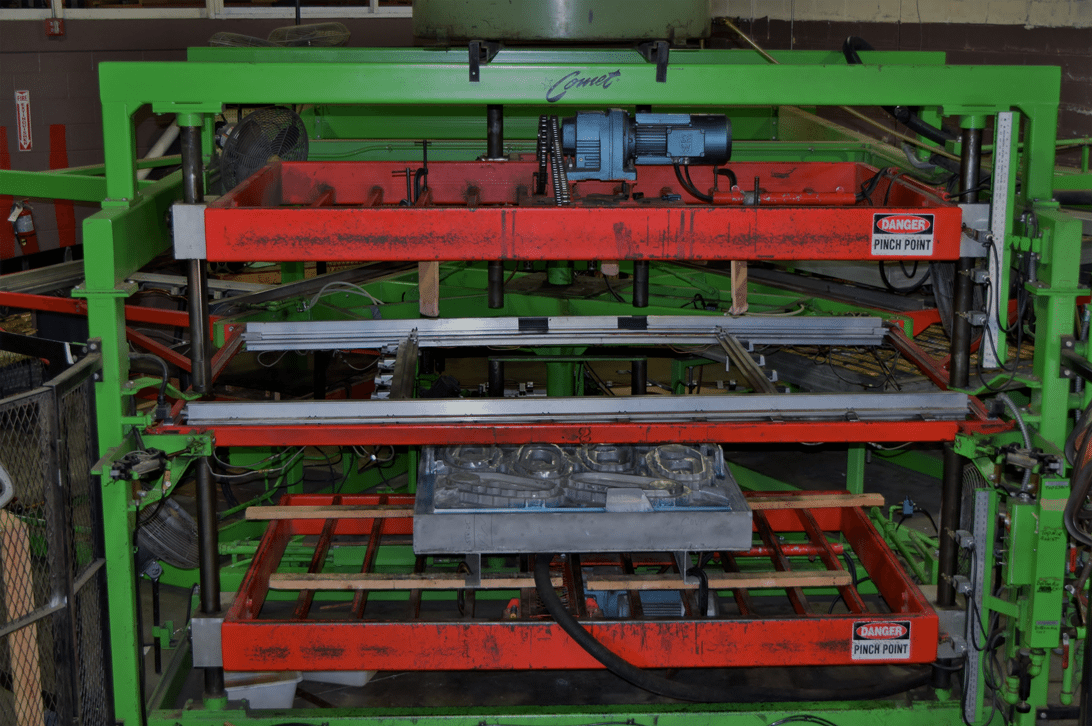

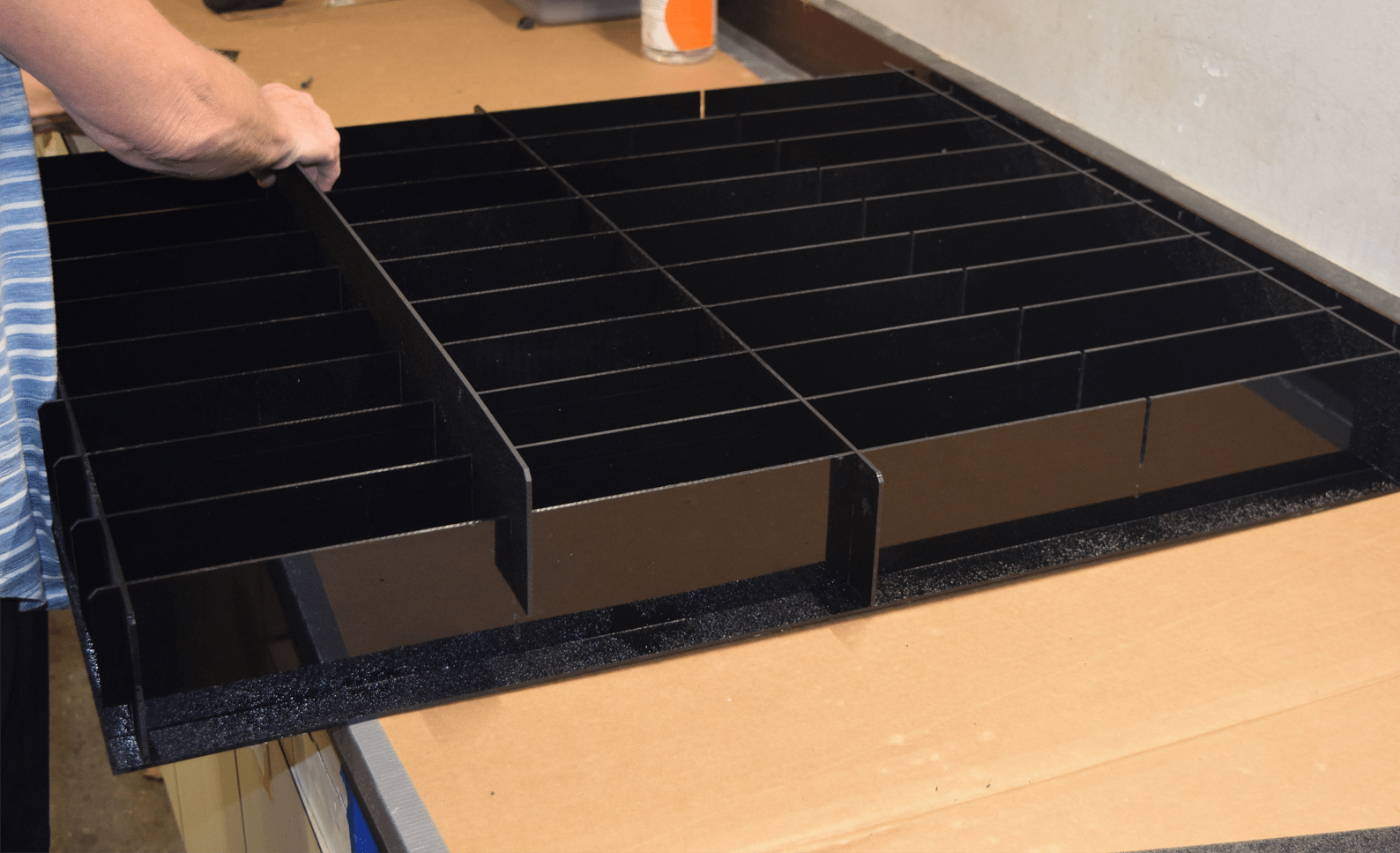

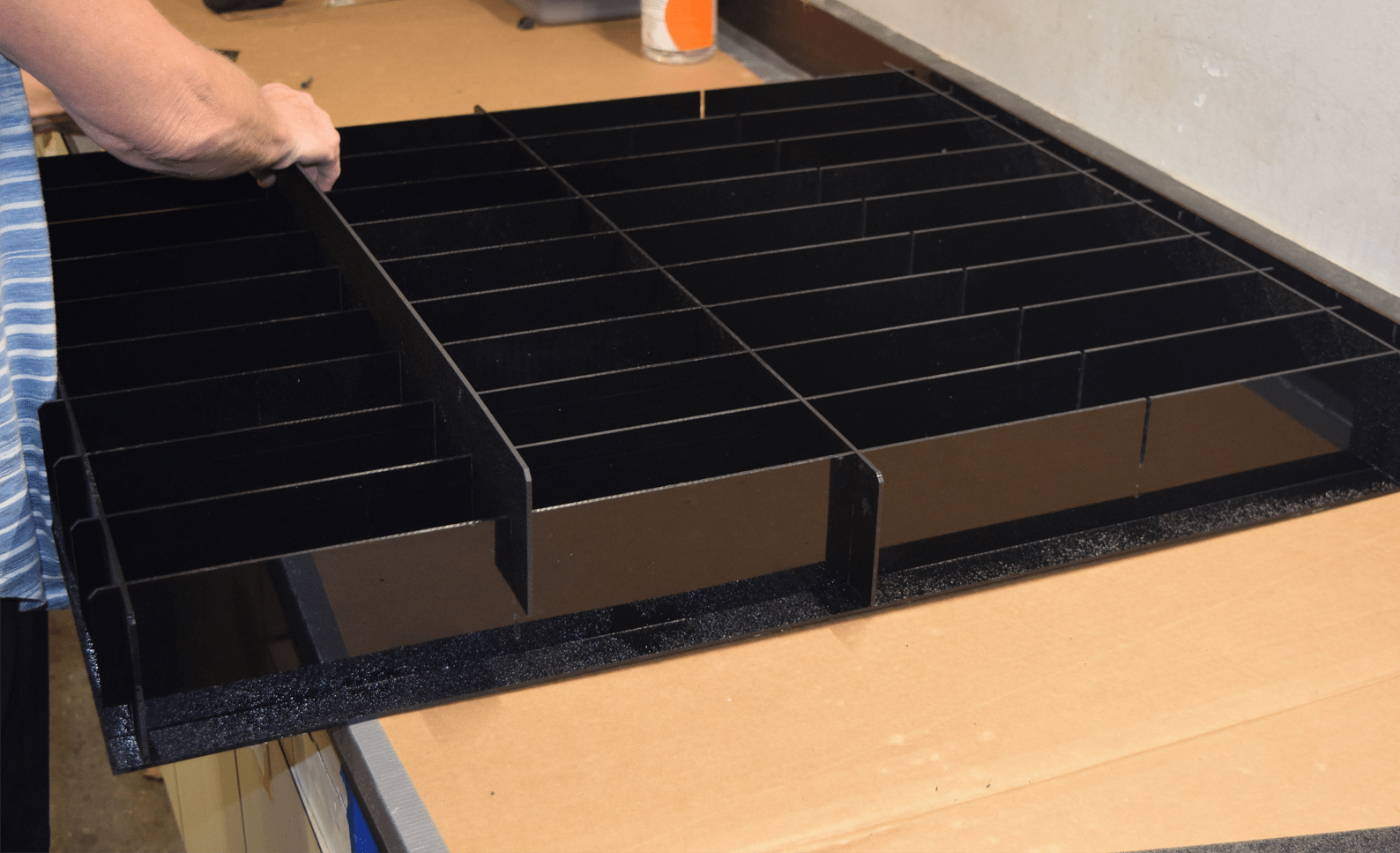

Heavy Gauge Vacuum Forming

Blue Ridge Thermoforming operates three heavy gauge rotary forming machines. Our largest part size is roughly 60”x100” however we have been able to push the limits on the machine a little beyond those dimensions. But our machines are capable of running much smaller parts, our smallest sheet size that we can run is a 12”x16”. The maximum draw depth of a part that we can run is approximately 24”. Material thickness can range from .03” to .5” thick. Although the equipment is capable of running many types of plastics, we commonly run HDPE, HMWPE, ABS, HIPS, PET/PETG, Polycarbonate, and PVC.

Heavy Gauge Vacuum Forming

Blue Ridge Thermoforming operates three heavy gauge rotary forming machines. Our largest part size is roughly 60”x100” however we have been able to push the limits on the machine a little beyond those dimensions. But our machines are capable of running much smaller parts, our smallest sheet size that we can run is a 12”x16”. The maximum draw depth of a part that we can run is approximately 24”. Material thickness can range from .03” to .5” thick. Although the equipment is capable of running many types of plastics, we commonly run HDPE, HMWPE, ABS, HIPS, PET/PETG, Polycarbonate, and PVC.

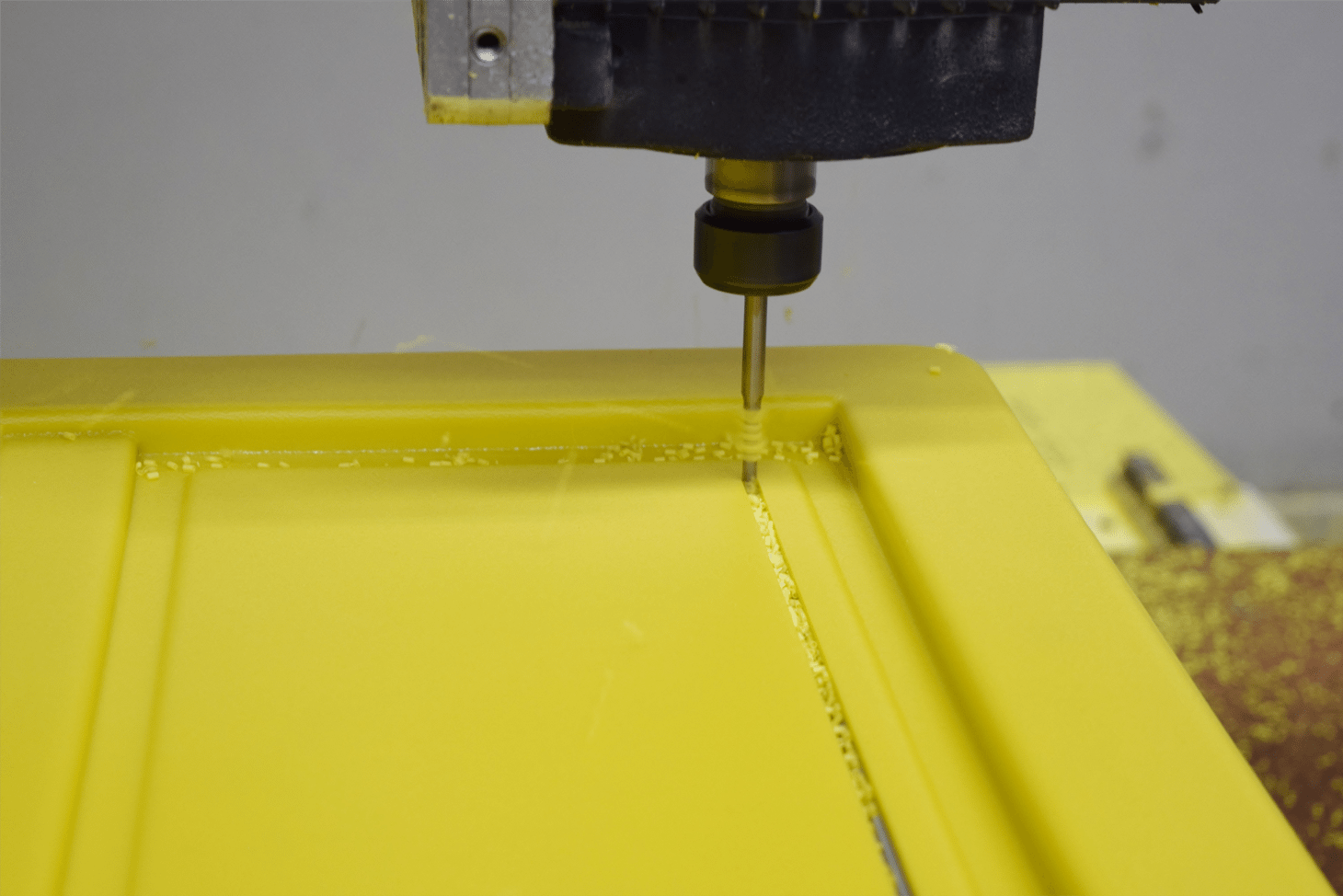

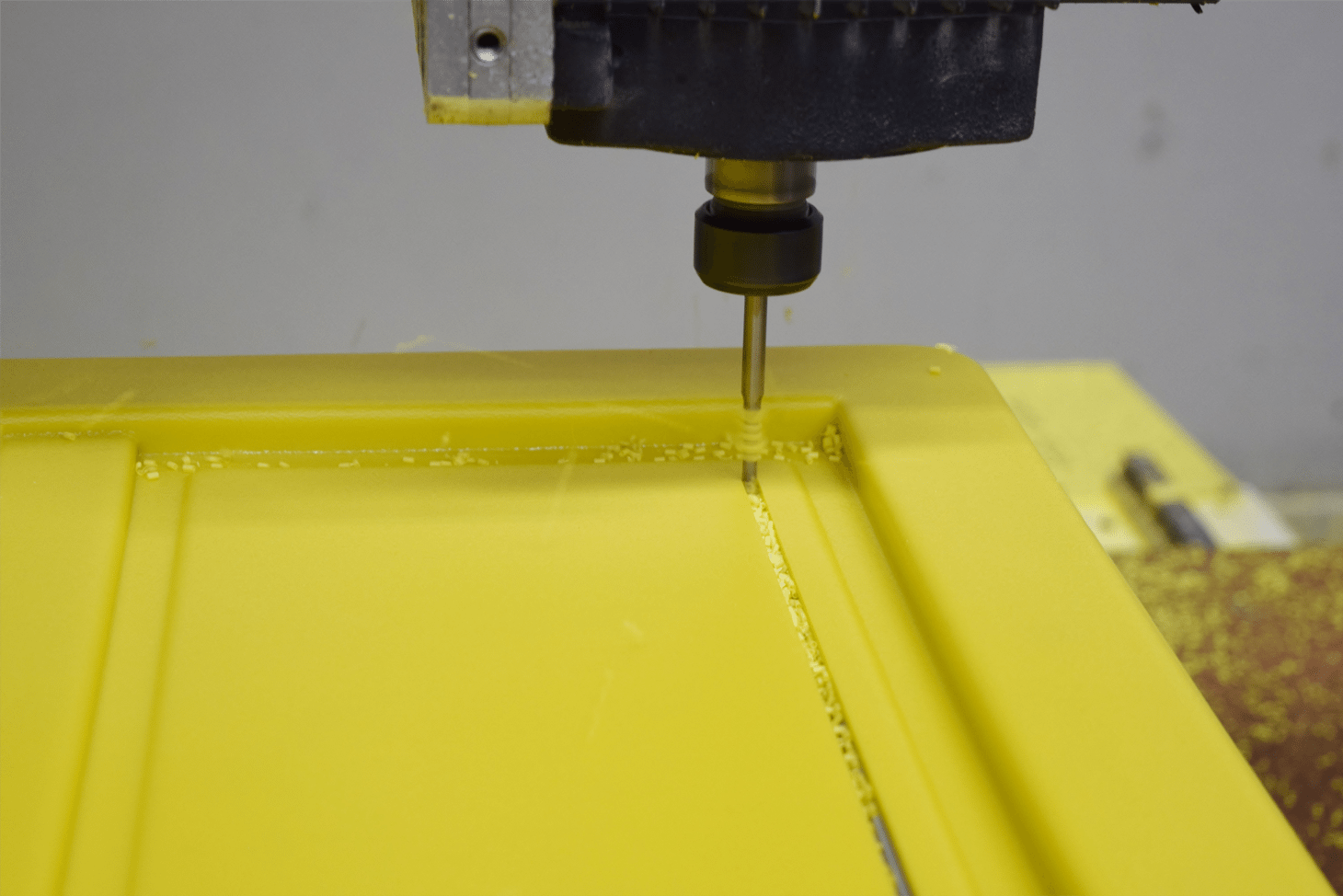

5 Axis Machining

Blue Ridge Thermoforming has a Thermwood 5-Axis CNC Router that can be used for precision cutting, trimming, and hole drilling/cutting. Most of the parts and trays made at Blue Ridge are cut by hand using a hand held router or saw. However, there are plenty of parts and trays that require much more precise cutting and the 5-axis router allows Blue Ridge the capability to provide this service to customers. In addition to precision cutting thermoformed parts, Blue Ridge can also machine other plastics. We commonly machine Pelican, Storm, and other cases for customers.

5 Axis Machining

Blue Ridge Thermoforming has a Thermwood 5-Axis CNC Router that can be used for precision cutting, trimming, and hole drilling/cutting. Most of the parts and trays made at Blue Ridge are cut by hand using a hand held router or saw. However, there are plenty of parts and trays that require much more precise cutting and the 5-axis router allows Blue Ridge the capability to provide this service to customers. In addition to precision cutting thermoformed parts, Blue Ridge can also machine other plastics. We commonly machine Pelican, Storm, and other cases for customers.

Fabrication and Assembly

Blue Ridge has the ability to add further value to parts through assembly and fabrication. We frequently assemble components using rivets, nuts/bolts, or screws. We also have experience and knowledge on solvent welding. Solvent welding is a way to adhere two plastic parts together permanently. We also commonly add foam pads to customer parts and can kit parts as desired by our customers.

Fabrication and Assembly

Blue Ridge has the ability to add further value to parts through assembly and fabrication. We frequently assemble components using rivets, nuts/bolts, or screws. We also have experience and knowledge on solvent welding. Solvent welding is a way to adhere two plastic parts together permanently. We also commonly add foam pads to customer parts and can kit parts as desired by our customers.

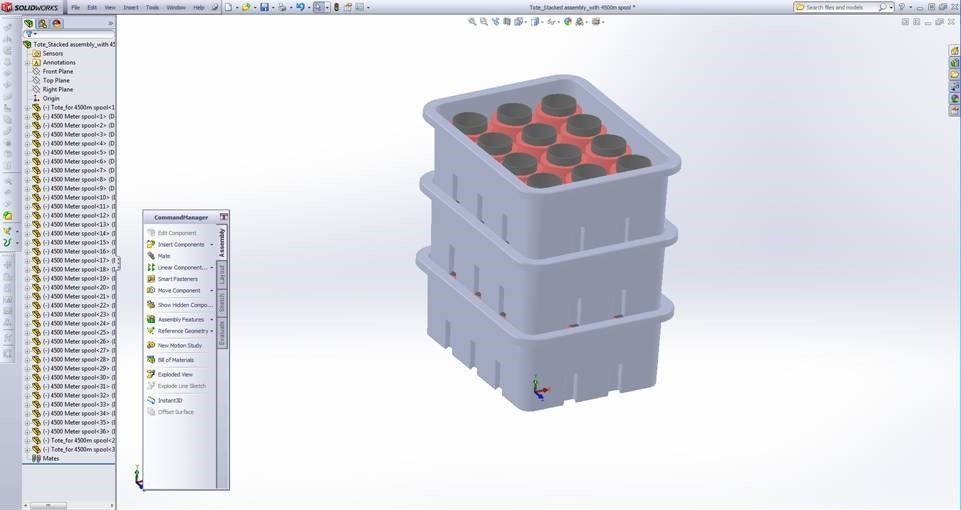

Design and Development

Blue Ridge Thermoforming has over 30 years of experience in designing and developing vacuum formed trays, packaging, and equipment covers. We specialize in providing innovative answers to challenges of pack density, product protection, and user functionality. We work with some of the most talented and experienced designers in this industry. All of our design work is done in SolidWorks. SolidWorks gives us the ability to review projects with customers before moving forward with prototypes and tools.

Design and Development

Blue Ridge Thermoforming has over 30 years of experience in designing and developing vacuum formed trays, packaging, and equipment covers. We specialize in providing innovative answers to challenges of pack density, product protection, and user functionality. We work with some of the most talented and experienced designers in this industry. All of our design work is done in SolidWorks. SolidWorks gives us the ability to review projects with customers before moving forward with prototypes and tools.